|

Installation Instructions for Model 50 and 100 Zinc Conductor Weights |

|

|

BARE CONDUCTOR INSTALLATION INSTALLATION OVER CONDUCTOR

PROTECTION DEVICES |

|

|

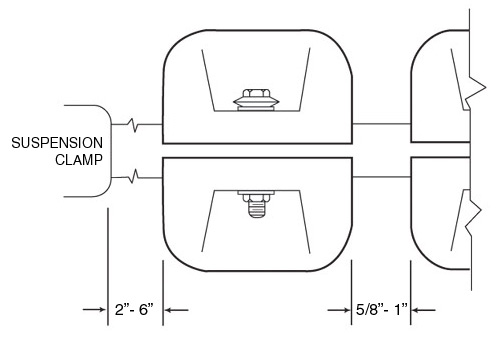

SERIAL INSTALLATION When two or more weights are required on a conductor on the same side of the sus-pension clamp, space the weights approximately 5/8” to 1” apart to avoid any possibility of contact between them. Installed weight contact might cause sharp protrusions with resulting corona emissions. |

| ASSEMBLY

INSTRUCTIONS FOR ZINC CONDUCTOR WEIGHTS |

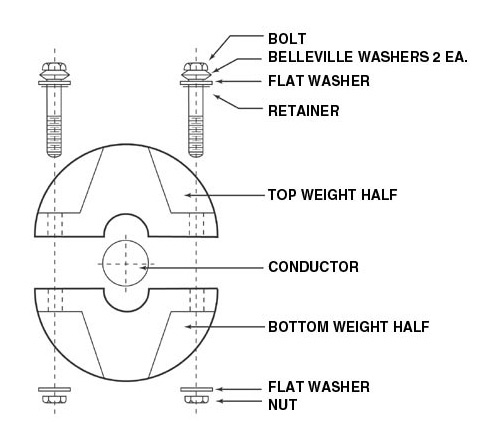

| 1. | Place one weight half on the conductor. |

| 2. | Bring the other half into position and drop the two bolt washer assemblies into place. |

| 3. | Slip a flat washer onto each bolt followed by a nut. |

| 4. | Snug up the nuts and check the alignment of the weight halves. |

| 5. | Torque the nuts to (30-35 lb./ft. for Model 50 Weights), (35-40 lb./ft. for Model 100 Weights). |

|

| CONTACT US BY E-MAIL |

NH INDUSTRIES

1003 E. 75th Ave.

Denver, CO 80229

Tel: 1- 303-287-6634

Fax: 1-303-287-0081